Revisiting Cross-Slit Illumination Rotation in EUV Lithography Systems

The optics used for illuminating masks in EUV lithography systems is quite complex and it really is not discussed enough [1]. Constraints on the illumination system affect the ability to maintain productivity while improving resolution. Improving resolution involves shrinking pitch, which restricts how much of the pupil can be used, i.e., the pupil fill. When the pupil fill is below 20%, light is excluded, essentially by being absorbed by the illumination system [2]. However, besides pupil fill, there is also the issue of pupil rotation [3]. A field lens with a toroidal surface reflects light so that a homogeneous intensity distribution fills the exposure field, which necessarily rotates the plane of incidence through the arc-shaped exposure field. The range of rotation is +/-30 degrees [4]. Evidence of rotation of the plane of incidence is shown in the horizontal-vertical bias across slit [5] as well as the pattern shift across slit [6].

Let’s now consider the implications for some key application cases for EUV lithography.

Two-Beam Imaging on 0.33 NA Systems

For line pitches of 40 nm and below, a 0.33 NA EUV system uses two-beam interference between the 0th (unscattered) and 1st (scattered) diffraction orders, which propagate along different angles in the system. The allowed illumination angles are restricted to leaf-shaped regions at the edge of the pupil, called the dipole leaves. Going from slit center to slit edge, these regions are rotated (Figure 1). As a result, some illumination angles are now coming from directions which cause the 1st diffraction order to not pass through to the wafer. For these angles, only the 0th order passes through, forming a background exposure of the resist. The image at wafer at the slit edge will be a mix of the desired two-beam interference and the undesired 0th order background, which is of lower contrast (NILS <2) than the two-beam interference pattern alone.

Figure 1. Cross-slit illumination rotation excludes a portion of the pupil from being used for two-beam imaging. The slit center may have the proper illumination (blue), while the slit edge (orange) will have some illuminations adding extra background light.

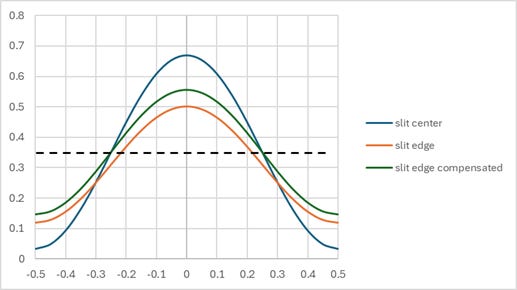

To eliminate the 0th order background illumination, we can restrict the illumination angles to a small subset of the dipole leaf. Often this leads to less than 20% of the pupil remaining. Since this results in system absorption, the throughput will take a hit, as the source power is effectively reduced significantly. On the other hand, we may choose to keep the whole dipole leaf, which would result in a degraded image but at least the throughput would be OK. This would also entail resizing features at the slit edge, relative to those at the center of the slit (Figure 2). In principle, the OPC would be continuously varying across the slit to compensate the effect of the illumination rotation, but the NILS still cannot be improved sufficiently for the edge to match the center.

Figure 2. Slit illumination rotation can be compensated according to position in the slit. Here the printing threshold is indicated by the dashed line. The OPC compensation allows both slit center and slit edge to print the target CD. However, the slit edge image contrast is degraded even after compensation.

The smaller the pitch, the larger the portion of the dipole leaf that cannot be used for two-beam interference at the slit edge. That is, the image at the slit edge would be degraded further.

Nevertheless, when the pitch is small enough (24 nm pitch, for example), the maximum allowed pupil fill is below 20% even without considering rotation.

Hexagonal patterns (Hexapole illumination)

Hexagonal patterns requiring hexapole illumination are encountered in the storage node landing locations in DRAM. This illumination mode is very sensitive to pupil rotation since the angular width of each pole is quite narrow; +/- 15 degrees tolerance can already be estimated to be impossible assuming the angular distance between poles to be equal to the angular width of the poles. As a result, as shown in Figure 3, the illumination angles at the slit edge may be shifted completely away from their originally intended directions maintained at the slit center.

Figure 3. Pupil rotation of hexapole illumination for storage node landing locations of 11nm-class DRAM. The hexapole illumination is essentially rotated out of place, beyond the tight angle tolerance.

Unlike the dipole leaf case for two-beam imaging, which had some overlap upon rotation, the illumination angles are entirely shifted so that entirely different images are produced (Figure 4).

Figure 4. Left: image under proper hexapole illumination. Right: image under rotation of hexapole illumination as in Figure 3. Vertical lines are produced in the diffraction pattern, which are imprinted on to the image.

Compared to the earlier case of dense lines, compensating by OPC adjustment across slit would actually be impossible due to the dissimilarity of the diffraction patterns from the rotated hexapole, e.g., vertical lines are imprinted on to the image.

High-NA Status

The most recent update on the High-NA (0.55 NA) EUV system [7] indicates that the cross-slit pupil rotation is addressed with a new illuminator design. The degree to which it is eliminated would be confirmed by measuring the horizontal-vertical CD and pattern shift difference across slit.

The installation of High-NA EUV systems has begun, but their use still warrants some caveats:

For the same mask scan time, the High-NA system has half the throughput of a 0.33 NA system. It’s because during that scan time, only a half-field of 26 mm x 16.5 mm is scanned on the High-NA wafer instead of the conventional 26 mm x 33 mm field size for other lithography tools [7].

Large die layouts need to be cut in half and stitched due to the same 26 mm x 16.5 mm half-field limitation [7].

Depth of focus of 0.55 NA is severely reduced compared to 0.33 NA [8].

Stochastic defectivity is the key limiter of EUV lithography resolution, rather than NA [9]. This is essentially tied to the resist absorption and electron blur [10,11].

A Nuisance Solution

Legacy EUV systems are still expected to deal with the cross-slit rotation issues when cross-slit OPC compensation doesn’t help. However, using only a small portion of the arc-shaped field to limit the degree of rotation [12] wastes the unused portion of the exposure field, and will mean more exposure stops per wafer, causing throughput to suffer just as in the High-NA half-field case. For example, restricting to only +/- 15 degrees of rotation halves the used exposure slit width, requiring twice as many reticle and wafer scans, as well as stage steps in between.

At the same time, the lingering issues of stochastic defectivity [8] and blur [10,11] was already jeopardizing the use of single exposure direct print. Thus, although it is a nuisance solution, multipatterning can address more than one EUV issue at once. Enlarging the line pitch by a factor of two can allow a rotationally symmetric set of illumination angles, e.g., annular shape, to be used. EUV’s requirement for multipatterning will also drive multipatterning productivity improvements which can be applied to DUV [13]. Hexagonal patterns can be formed by crossing two intersecting line patterns formed by self-aligned multipatterning [14], or by directed self-assembly [15].

References

[1] EUV Lithography's Pupil Fill Tradeoff: Defocus Tolerance vs. Throughput (substack.com)

[2] M. van de Kerkhof et al., "Enabling sub-10nm node lithography: presenting the NXE:3400B EUV scanner," Proc. SPIE 10143, 101430D (2017).

[3] M. Antoni et al., “Illumination optics design for EUV lithography,” Proc. SPIE 4146, 25 (2000).

[4] M. van den Kerkhof et al., “High-transmission EUV pellicles supporting >400W source power,” Proc. SPIE 12051, 120510B (2022).

[5] G. McIntyre et al., “Modeling and Experiments of Non-Telecentric Thick Mask Effects for EUV Lithography,” Proc. SPIE 7271, 72711C (2009).

[6] M. Sugawara, G. R. McIntyre, “Assessment of CD and pattern position error caused by non-flat surface of mask and chuck,” 2007 International EUVL Symposium.

[7] J. van Schoot et al., J. Micro/Nanopattern. Mater. Metrol. 24, 011009 (2024); J. Zimmermann et al., Proc. SPIE 12750, 127500O (2023).

[8] S. Das et al., “Resolution improvement and dose reduction in logic and memory applications from low NA to high NA,” Proc. SPIE 13424, 1342413 (2025).

[9] P. Leray et al., “NA 0.33 EUV extension for HVM: Testing single patterning limits,” Proc. SPIE 13424, 1342403 (2025).

[12] A Forbidden Pitch Combination at Advanced Lithography Nodes

[10] F. Chen, A Realistic Electron Blur Function Shape for EUV Resist Modeling

[11] F. Chen, Impact of Varying Electron Blur and Yield on Stochastic Fluctuations in EUV Resist

[13] F. Chen, Routing and Patterning Simplification with a Diagonal Via Grid; F. Chen, Exploring Grid-Assisted Multipatterning Scenarios for 10A-14A Nodes

[14] N. Bae et al., “Advanced multiple patterning technologies for high density hexagonal hole arrays,” Proc. SPIE 11615, 116150B (2021).

[15] H-C. Wu et al., “Wet etch process for high resolution DSA patterning for advanced node DRAM,” Proc. SPIE 12957, 1295721 (2024).

This article was revised May 13, 2025.

TSMC also seemed to know about it, at one point, from their patent US9091930 https://patents.google.com/patent/US9091930 where they considered rotating patterns along the slit (Figures 3B, 4).

This pupil rotation is also disclosed in Zeiss's patent US6859515 https://patents.google.com/patent/US6859515B2/ see Figure 5