Oxidation, Outgassing, and Blistering: Materials Damage in EUV Lithography

Anything exposed to EUV light in an EUV lithography machine is basically being damaged.

2025 looks like the year everyone is reporting damage from EUV exposure affecting materials being used during EUV lithography. This article will be an update and overview of the damage to materials used in EUV lithography, from the exposure to EUV radiation.

EUV resists

Resists are the key carbon-based materials used in EUV lithography. Outgassing experiments have confirmed chemical modification that increases with dose [1], and resist thickness loss that increases with dose has also been confirmed [2]. This year, a US team confirmed the simultaneous loss of thickness and chemical degradation proportional to EUV dose, using PtBMA as a model polymer [3]. A 10% thickness loss was found at a dose of 50 mJ/cm2, increasing to 40% at 300 mJ/cm2. Besides acid deprotection or crosslinking, there are other mechanisms through which the resist is altered chemically by EUV exposure, such as through other complex molecular fragmentation. This means we can now have stochasticity of chemical modification contributing to the stochasticity of EUV resist exposure that causes defects, roughness, and edge placement errors. There can be a randomness in the number of events of molecular alteration, e.g., scission vs. deprotection vs. crosslinking, not just the randomness in the number of photons or electrons. Moreover, the etch resistance of the resist is also affected, due to reduced thickness and chemical composition change. This could aggravate the after-etch defectivity.

Silicon-based pellicle materials

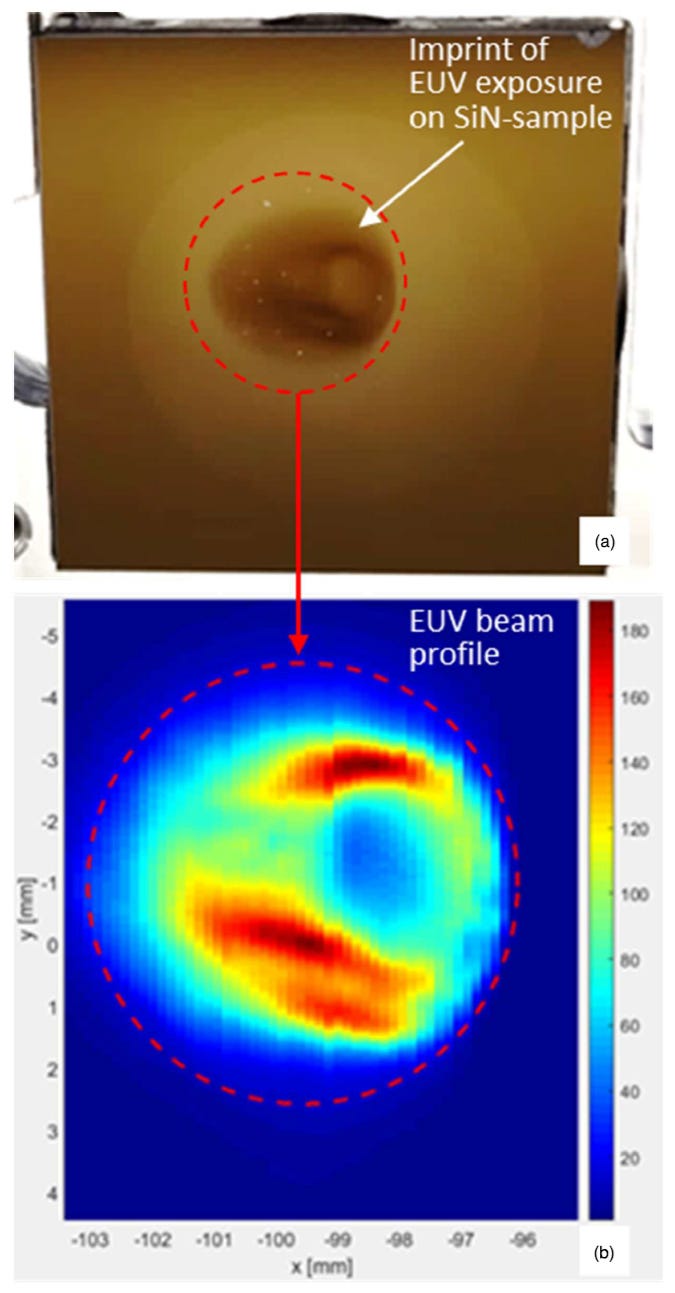

Current EUV pellicles are Si-containing [4]. This year, TNO reported that after EUV exposure, a 50 nm thick silicon nitride film was darkened to a degree corresponding to the EUV beam profile intensity (Figure 1).

Figure 1. (Top) Imprint of EUV exposure on SiN sample; (Bottom) EUV beam profile in defocused mode. Source: Ref. [4].

A big concern for silicon-based pellicles is the outgassing of silicon from the radiation exposure and/or the hydrogen plasma exposure. In the illuminated spot of Figure 1, silicon bond reconstruction had occurred. However, silicon outgassing had not been detected; it is possible this is due to the temperature being relatively low (50 C). The chemical composition of the pellicle film may be altered just as in the case of the EUV resist [4]. In any case, the limited lifetime of current pellicles has been a serious enough issue [5] that carbon nanotubes are being considered as the replacement [4,6].

Multilayer mirrors

In EUV lithography, multilayer mirrors are found in the EUV light collector, on the EUV mask, and in the projection optics. These are necessary as EUV light cannot be transmitted through materials unless they are very thin (like pellicle films). The mirrors consist of many molybdenum/silicon bilayers capped by a top layer, usually ruthenium. For different locations in the EUV lithography system, the mirror lifetime is determined by different factors.

Collector mirrors

EUV light is generated from a laser-produced tin plasma. Tin must be ionized in the plasma state to emit EUV light in the target wavelength range (13.2-13.8 nm). However, the mirrors which collect the EUV light and reflect them downstream are also exposed to the tin plasma. Therefore, tin may coat the mirrors, reducing the reflectivity. Hydrogen is therefore added also as a plasma to enable cleaning of the mirrors, via the reaction Sn (s) + 4 H (g) => SnH4 (g) [7]. The presence of tin on the ruthenium capping layer facilitates the diffusion of hydrogen through the ruthenium to the multilayer below [8,9]. Once there, the hydrogen becomes trapped, leading to a bubble formation that deforms the surface, forming a blister [10]. As of the end of 2024, EUV collectors lose at least 10% reflectivity after about 500 billion pulses, just under 4 months [11].

EUV masks

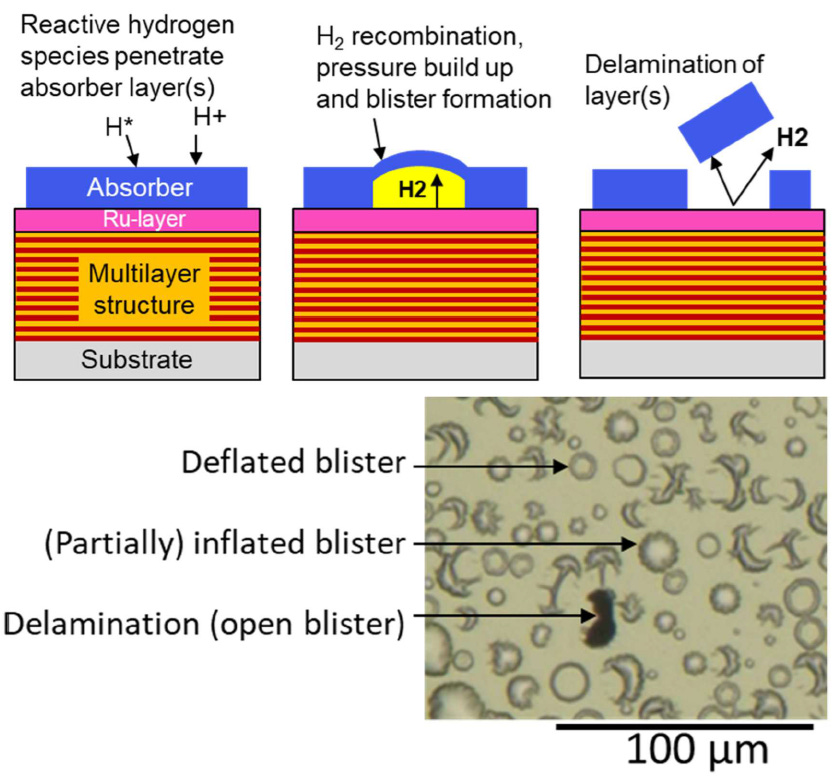

The environment of the EUV mask is less hostile than that of the collector mirror, in that there is no risk of tin contamination. The hydrogen diffusion is therefore much slower. However, hydrogen blistering, due to diffusion through the ruthenium capping layer, still happens, as shown also by TNO this year [4] (Figure 2). In this case, the hydrogen pressure is enough to push off the ruthenium capping layer as well as the absorber on top of it. According to TSMC patent US12287581, when the number of wafers exposed by the EUV radiation tool using the photomask exceeds 10,000, the blister defects tend to occur [12]. Assuming a tool throughput ~3000 wafers a day, this means that blister defects will become a problem every 3 days or so, around twice a week [13].

Figure 2. (Top) Delamination of EUV mask when hydrogen pressure builds up underneath the absorber; (Bottom) Visible light microscope image of ruthenium layer on quartz featuring blisters induced by hydrogen radicals. Source: Ref [4].

The ambient inside the EUV machine may also contain small traces of water, which would result in oxygen being present [4,14]. The oxygen can also diffuse through to the multilayer causing localized oxidation that will also distort the overlying layers. In fact, as NYCU and TSMC reported this year at the Photomask Technology conference, every time the mask is cleaned, it will be exposed to an oxidizing ambient, which provides oxygen that can diffuse through the ruthenium capping layer as well [15]. Doping the ruthenium may allow it to capture the oxygen, but will oxidize it as a result, changing the reflectivity due to oxygen’s efficient EUV absorption [4].

Projection mirrors

The projection mirrors in an EUV lithography machine are further downstream of the mask. The EUV light power density is not as high at each of the six mirrors as on the mask [16]. Thus, the hydrogen is not driven in as significantly at these mirrors as on the mask or at the collector. Thus, hydrogen blistering is less of a risk. On the other hand, when the hydrogen’s presence is reduced, the oxygen’s presence from the water contamination could become greater. Thus, the lifetime of the projection mirrors could be limited by the time to oxidize sufficiently to affect the reflectivity. The lifetime is expected to be inversely proportional to the incident power density but proportional to the area of the mirror [16]. The first mirror right after the mask has the shortest lifetime, while the last mirror (defining the numerical aperture), has the longest lifetime. For a 2.66e-6 mbar water-vapor pressure, a first mirror with 127 cm2 and 17.5 mW/cm2 power density had a lifetime of 0.3 years, while a last mirror with 536 cm2 area and 0.3 mW/cm2 power density had a lifetime of 18.5 years [16].

Construction materials

This year, ASML reported on the impact of stray EUV light exposure on stainless steel surfaces in the ambient of the EUV lithography machine [14]. The steel surface in the scanner is partially exposed to stray or scattered EUV light while at the same time more globally exposed to the EUV-plasma. While the steel is stable under exposure to hydrogen plasma (as expected), surprisingly, the EUV-irradiated part is clearly oxidized or corroded. While there is no expected concern for structural integrity, the possibility of particle generation and adhesion remains. Thus, this could easily become a maintenance issue.

Summary

The picture we get from all these reported results is that any material exposed to EUV light will get damaged. Polymers and thin films are chemically modified, which often leads to outgassing. Thicker structures can trap hydrogen or oxygen underneath the surface, which can provide the seed for blisters and/or particles. The oxygen can also oxidize the crucial layers used for reflecting EUV light, leading to reduced doses at the wafer which requires lower throughput to compensate. Apparently, every material used in EUV lithography will be a consumable, and an expensive one at that.

References

[1] F. Chen, EUV Resist Degradation with Outgassing at Higher Doses.

[2] F. Chen, Resist Loss Prohibits Elevated EUV Doses.

[3] O. Kostko et al., “Extreme ultraviolet induced chemistry in polymer thin films,” Proc. SPIE 13428. 134282K (2025).

[4] L. Poirier et al., “Extreme ultra-violet beamline research facility and studies of optical elements for nanolithography,” Jpn. J. Appl. Phys. 54, 126501 (2025); https://doi.org/10.35848/1347-4065/ae187c.

[5] F. Chen, EUV Lithography Without Pellicles: Accounting for Low Yields.

[6] Global Technology Research, Carbon Nanotube (CNT)- The Next Big Thing for EUV Pellicle?, Jan. 14, 2025.

[7] V. M.C. Crijns, “Hydrogen atom based tin cleaning,” Eindholven University of Technology Master’s Thesis, 2014.

[8] C. Onwudinanti et al., “Tin, The Enabler—Hydrogen Diffusion into Ruthenium,” Nanomaterial (Basel) 9, 129 (2019); doi: 10.3390/nano9010129.

[9] S-C. Wang, Protecting EUV mirrors: how tin and plasma shape hydrogen uptake in ruthenium films, Oct. 16,2025.

[10] F. Chen, Hydrogen Blistering in EUV Multilayers.

[11] J. van Schoot et al., “Next step in Moore’s law: high NA EUV system overview and first imaging and overlay performance,” J. Micro/Nanopattern. Mater. Metrol. 24, 011009 (2025).

[12] U.S. Patent 12287581, assigned to TSMC.

[13] F. Chen, TSMC Confronts Mask Defects from EUV Hydrogen Plasmas.

[14] M. van de Kerkof, “Interaction between EUV and construction materials,” Proc. SPIE 13533, 1353307 (2025).

[15] C-H. Wang et al., “Novel capping layer evaluation for EUV mask,” Proc. SPIE 13687, 1368707 (2025).

[16] S. Bajt et al., “Design and performance of capping layers for extreme-ultraviolet multilayer mirrors,” Appl. Opt. 42, 5750 (2003).

Does it make sense to cover some of the stainless surfaces with CVD deposited heavier metals of higher atomic number for improved stopping power to the high energy photons? Tantalum or chrome are used on masks as photon absorbers, maybe it makes sense to cover other surfaces too? Yes coatings cost money and economic factors may trump all ideas to ameliorate frequent maintenance. Is there a second life for parts degraded by radiation exposure? Re-using parts somewhere else with less stringent requirements may help with economics. Great article, Dr Chen!